山東焊接專(zhuān)機 : 焊接專(zhuān)機和焊接機器人的區別

來(lái)源:http://m.aplwebs.com/ 發(fā)布時(shí)間:2024-05-24 瀏覽次數:0

在現代制造業(yè)中,焊接是一項非常重要的工藝,被廣泛應用于汽車(chē)、航空航天、建筑和許多其他行業(yè)。為了提高生產(chǎn)效率和焊接質(zhì)量,焊接機器人和焊接專(zhuān)機成為焊接工藝中的兩種常見(jiàn)選擇。本文將探討焊接專(zhuān)機和焊接機器人之間的區別。

Welding is a very important process in modern manufacturing, widely used in automotive, aerospace, construction, and many other industries. In order to improve production efficiency and welding quality, welding robots and welding machines have become two common choices in welding processes. This article will explore the differences between welding machines and welding robots.

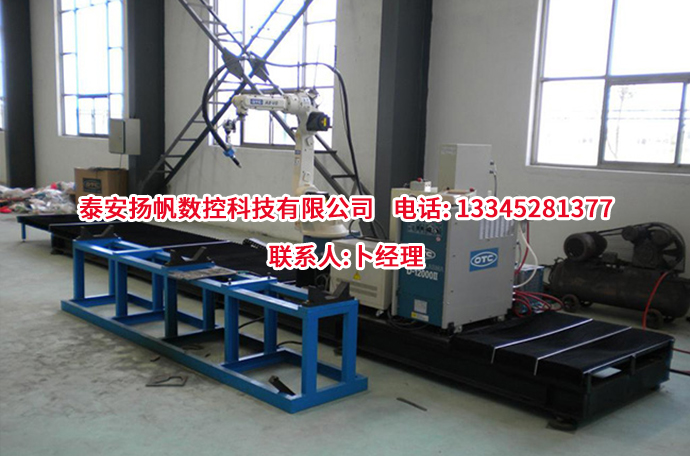

自動(dòng)化控制系統推廣到焊接行業(yè)后,便出現了焊接機器人、焊接專(zhuān)機兩種自動(dòng)焊接機械。雖然都是焊接專(zhuān)用機械,但其功能和適用環(huán)境還是有一些差異。焊接機器人與焊接專(zhuān)機的區別如下:

After the promotion of automation control systems to the welding industry, two types of automatic welding machinery, welding robots and welding specialized machines, emerged. Although they are all specialized welding machinery, there are still some differences in their functions and applicable environments. The difference between welding robots and welding specialized machines is as follows:

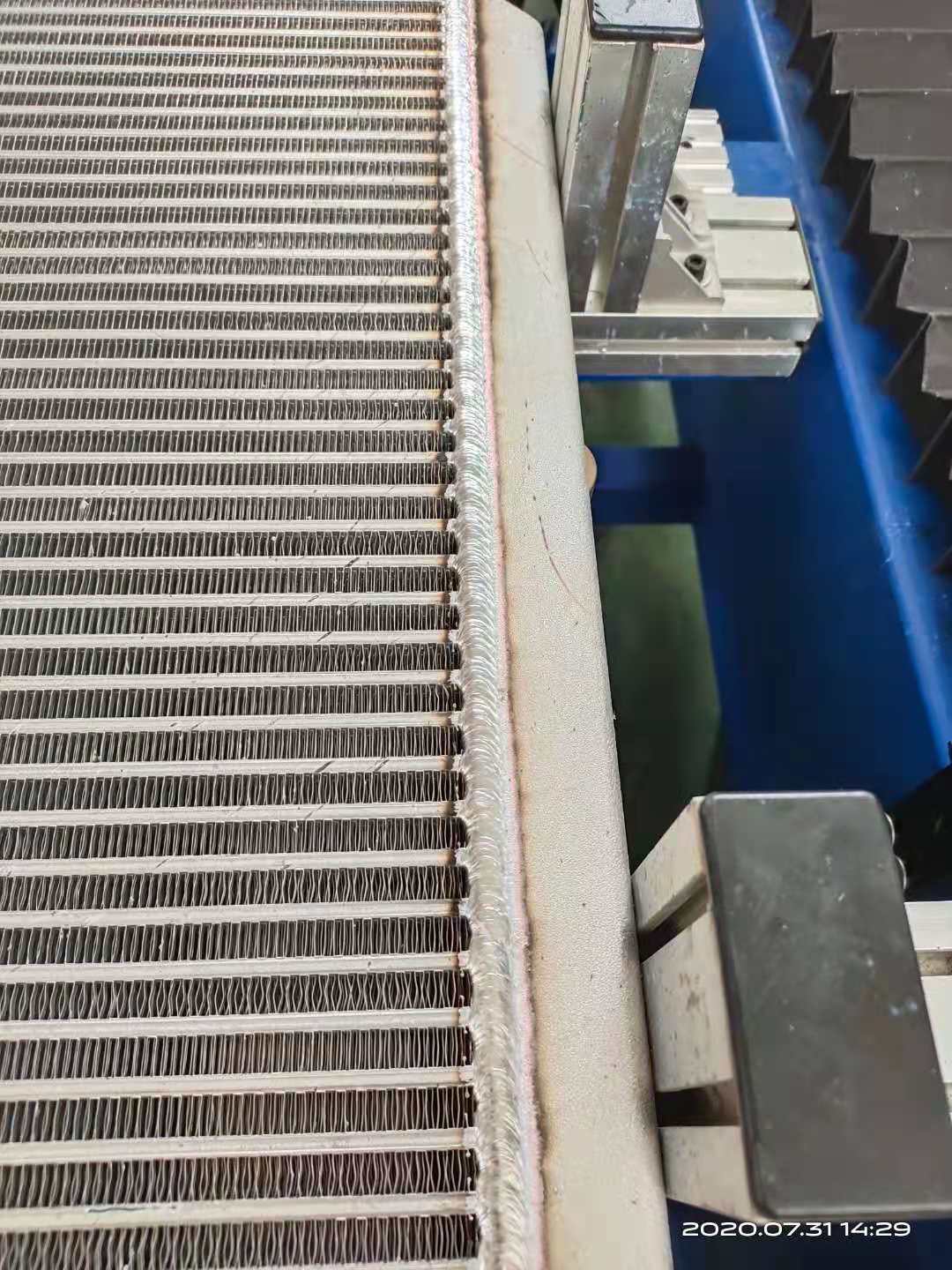

,從造價(jià)成本方面而言,焊接專(zhuān)機要比焊接機器人使用成本更低,更具優(yōu)勢,但大部分的工廠(chǎng)依會(huì )選擇焊接機器人,因為焊接專(zhuān)機是專(zhuān)門(mén)針對某類(lèi)特殊的產(chǎn)品而的自動(dòng)化設備,多選用伺服X、Y、Z軸三個(gè)方,通常只是用來(lái)焊接環(huán)形、直焊縫,使用具有局限性。焊接專(zhuān)機可裝配4~5個(gè)焊頭,裝配后的總體效率比焊接機器人高。

Firstly, in terms of cost, welding machines have a lower usage cost and more price advantage than welding robots. However, most factories choose welding robots because welding machines are automation equipment specifically designed for a specific type of product, and they often choose to serve X Y. The three directions of the Z-axis are usually only used for welding circular and straight welds, and their use has limitations. The welding machine can assemble 4-5 welding heads, and the overall efficiency after assembly is higher than that of welding robots.

而焊接機器人對工件和環(huán)境適用性高一些,靈活性強。它采用6個(gè)伺服控制,能夠在焊接范圍內進(jìn)行3D立體不規則的焊接,因此相對性高一些。

And welding robots have higher adaptability to workpieces and environments, with strong flexibility. It adopts 6 servo controls and can perform 3D irregular welding within the welding range, so the price is relatively high.

兩者的不同體現在不同場(chǎng)合使用時(shí)的更佳選擇:焊接平面上的直縫、圓縫,要用焊接專(zhuān)機。但焊接產(chǎn)品變了尺寸或樣式的話(huà),那就要選擇靈活性更高的焊接機器人了。只需重新編寫(xiě)程序參數,就可以再次運用了。

The difference between the two is reflected in the better choice when used in different situations: for straight and circular seams on the welding plane, a welding machine should be used. But if the size or style of the welding product changes, then it is necessary to choose a welding robot with higher flexibility. Just rewrite the program parameters and you can use them again.

伴隨著(zhù)焊接機器人在各行各業(yè)的廣泛應用,焊接機器人為滿(mǎn)足更多作業(yè)需求,有時(shí)還是會(huì )另外裝配1個(gè)或幾個(gè)外界軸。換句話(huà)說(shuō),外界軸就是跟焊接機器人相接的輔助動(dòng)作系統,來(lái)協(xié)助機器人的焊接動(dòng)作,可以同時(shí)滿(mǎn)足焊接姿勢的應變,也可以更迅速地完成焊接工作。

With the widespread application of welding robots in various industries, welding robots sometimes assemble one or several external axes to meet more operational needs. In other words, the external axis is an auxiliary action system connected to the welding robot to assist in the welding action, which can simultaneously meet the strain of the welding posture and complete the welding work more quickly and efficiently.

以上是關(guān)于 山東焊接專(zhuān)機 的介紹,若想了解相關(guān)知識可請點(diǎn)擊:http://m.aplwebs.com 我們將會(huì )全心全意為您提供滿(mǎn)分服務(wù),歡迎您的來(lái)電!

The above is an introduction to Shandong welding machines. If you want to learn more about related knowledge, please click: http://m.aplwebs.com We will wholeheartedly provide you with full score service. Welcome to call us!

上一篇:山東自動(dòng)焊接設備:自動(dòng)焊接技術(shù)有哪些?

下一篇:自動(dòng)化焊接設備的種類(lèi)介紹