大罐環(huán)縫自動(dòng)焊接工藝介紹

來(lái)源:http://m.aplwebs.com/ 發(fā)布時(shí)間:2024-02-10 瀏覽次數:0

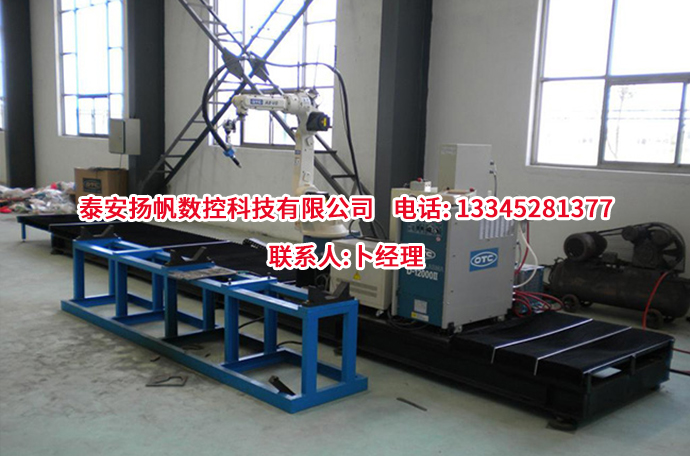

大罐環(huán)縫自動(dòng)焊接工藝是現代焊接技術(shù)中的一項重要應用,它在大型罐體制造中起到了關(guān)鍵的作用。本文將介紹大罐環(huán)縫自動(dòng)焊接工藝的原理、特點(diǎn)和應用。

The automatic welding process for large tank circumferential seams is an important application in modern welding technology, which plays a crucial role in the manufacturing of large tank bodies. This article will introduce the principle, characteristics, and application of automatic welding technology for large tank circumferential seams.

大罐環(huán)縫自動(dòng)焊接工藝是一種采用機器人或自動(dòng)化設備進(jìn)行焊接的工藝。它通過(guò)預先編程的焊接路徑和參數,實(shí)現對罐體環(huán)縫的自動(dòng)化焊接。與傳統手工焊接相比,大罐環(huán)縫自動(dòng)焊接工藝具有以下幾個(gè)顯著(zhù)特點(diǎn)。

The automatic welding process for large tank circumferential seams is a process that uses robots or automated equipment for welding. It achieves automated welding of tank body circumferential seams through pre programmed welding paths and parameters. Compared with traditional manual welding, the automatic welding process for large tank circumferential seams has the following significant characteristics.

,大罐環(huán)縫自動(dòng)焊接工藝可以提高焊接效率。由于焊接路徑和參數預先設定,機器人或自動(dòng)化設備可以快速、準確地完成焊接任務(wù),大大節省了人力和時(shí)間成本。

Firstly, the automatic welding process for large tank circumferential seams can improve welding efficiency. Due to the pre-set welding path and parameters, robots or automated equipment can quickly and accurately complete welding tasks, greatly saving labor and time costs.

其次,大罐環(huán)縫自動(dòng)焊接工藝能夠提高焊接質(zhì)量。機器人或自動(dòng)化設備具有穩定的焊接性能和精確的焊接控制,可以確保焊縫的一致性和質(zhì)量,減少焊接缺陷的產(chǎn)生。

Secondly, the automatic welding process for large tank circumferential seams can improve welding quality. Robots or automated equipment have stable welding performance and precise welding control, which can ensure the consistency and quality of welds and reduce the occurrence of welding defects.

第三,大罐環(huán)縫自動(dòng)焊接工藝具有較高的性。焊接過(guò)程中,操作人員可以遠離焊接區域,減少了風(fēng)險和焊接事故的發(fā)生。

Thirdly, the automatic welding process for large tank circumferential seams has high safety. During the welding process, operators can stay away from the welding area, reducing safety risks and the occurrence of welding accidents.

大罐環(huán)縫自動(dòng)焊接工藝在石油化工、冶金、船舶制造等領(lǐng)域有著(zhù)廣泛的應用。例如,在石油儲罐制造中,大型儲罐常常需要進(jìn)行環(huán)縫焊接,傳統的手工焊接效率低下且難以保證質(zhì)量,而采用大罐環(huán)縫自動(dòng)焊接工藝可以提高生產(chǎn)效率和焊接質(zhì)量,降低生產(chǎn)成本。

The automatic welding process for large tank circumferential seams has a wide range of applications in fields such as petrochemicals, metallurgy, and shipbuilding. For example, in the manufacturing of oil storage tanks, large tanks often require circumferential welding, and traditional manual welding is inefficient and difficult to ensure quality. However, adopting automatic circumferential welding technology for large tanks can improve production efficiency and welding quality, and reduce production costs.